AlphaSpace

Explore every feasible completion design to find the true optimum.

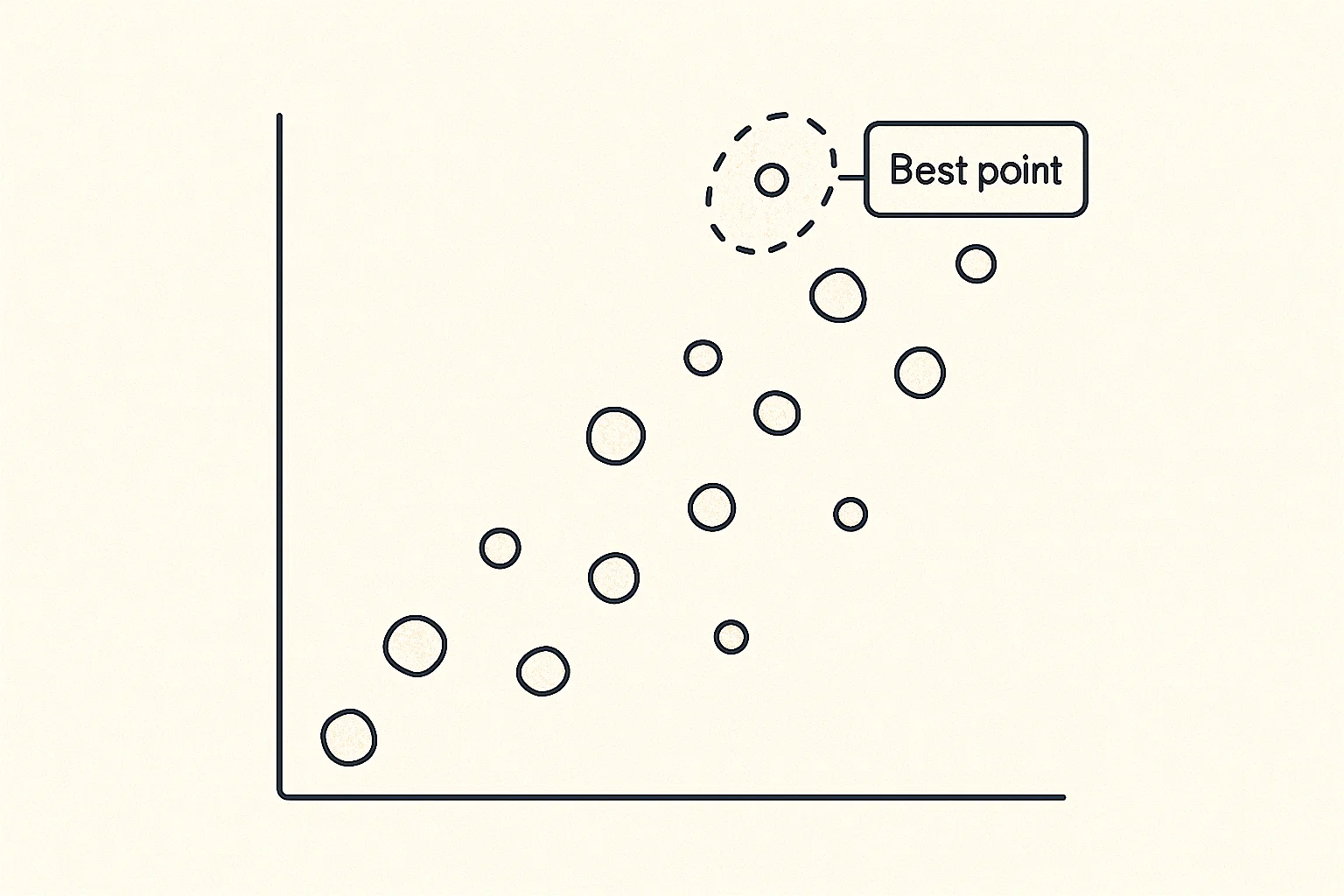

Exhaustive solution space exploration

AlphaSpace expands on AlphaTally by exploring every viable casing configuration. Harness massive compute to uncover designs that manual processes miss, while staying grounded in your engineering constraints.

• Works directly from AlphaTally outputs and field constraints.

• Surfaces the absolute best designs across trillions of permutations.

Explore All Solutions

Evaluate every feasible completion to pick the optimal design with evidence.

Exhaustive coverage

Maps the full solution space so no viable design is overlooked.

Highlight the best

Ranks every option to surface the absolute best performers for your objectives.

Handle edge cases

Finds workable solutions even in challenging scenarios where manual iteration stalls.

Advanced Optimization

Tap massive parallel compute to balance competing objectives and deliver elite completions.

Massive computing power

Leverages thousands of CPUs to solve workloads beyond manual reach.

Multi-objective balance

Weighs cost, performance, and risk to provide the most efficient paths.

Real-world fidelity

Models complex zone interactions to reflect field conditions.

Maximum Flexibility

Adapt the exploration to your rules, constraints, and team processes.

Engineer your way

Control parameters, constraints, and objectives for each study.

Share results instantly

Integrates with AlphaTally, Frac Design, and SmartRun so teams collaborate in one platform.

Stay in the browser

100% cloud-based with audit trails and role-based access built in.

Unlock the full completion design space

Discover how AlphaSpace can deliver you the best designs faster.