Deep Insight

Deep Insight Helps Client Diagnose Casing Failures in Coal Seam Gas Wells - A Digital Twin Case Study

Apr 24, 2023

Coal Seam Gas (CSG) is an unconventional gas that has been developed extensively in Queensland. As with any field, maintaining optimal well performance is crucial for maximizing production and revenue.

The variations in subsurface formations and the large numbers of wells required for CSG production lead to many different challenges arising.

For the purposes of this article we will imagine an example where an operator in the CSG industry faces an undiagnosed issue causing poor well performance across several wells. An initial physical investigation determines that casing failures are impacting the well performance, but the reason for the casing failures is not clear.

Well casings are an essential component of coal seam gas (CSG) wells. These wells are typically drilled vertically through the layers of rock to access the coal seam deposits. The casings are used to protect the wellbore and prevent the collapse of the rock layers around it. In addition, the casings are designed to prevent the infiltration of water or other fluids from the surrounding rock layers into the wellbore, which could impact the quality of the gas being extracted. Well casings are typically made of steel or other strong materials that can withstand the high pressures and temperatures encountered in the wellbore. The proper design and installation of well casings is crucial for the safe and efficient operation of CSG wells.

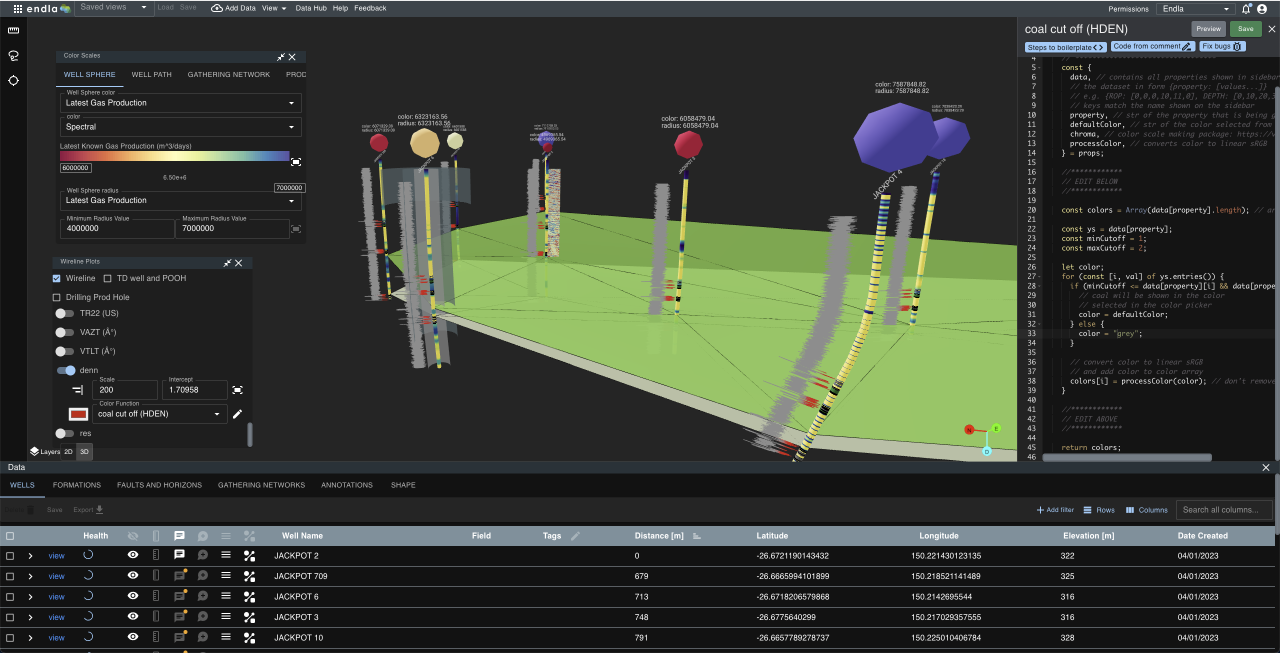

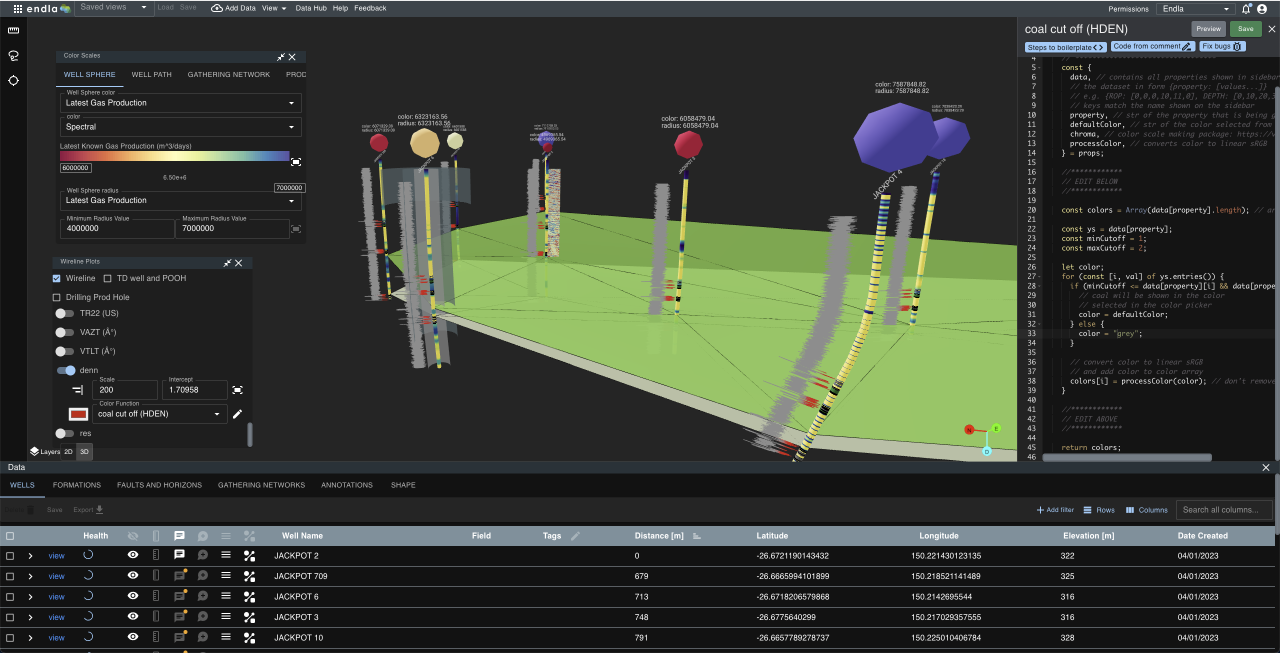

Deep Insight is a powerful data analysis tool that provides 3D visualization and annotation capabilities. It works as a Digital Twin of any of any oil or gas asset, built off the business’ data and providing insights to the client.

In the example given, the casing failures are diagnosed using Deep Insight's Digital Twin capabilities. By using the tool to get an overview of the field and all the wells with associated data the wells with issues are compared against similar wells that are performing as expected.

People can process data much more effectively when it is visualized rather than when it is presented in a tabular form. This is because our brains are wired to process visual information faster and more efficiently than textual information. By representing data visually, we can quickly identify patterns, trends, and outliers that might be difficult to discern in tabular data. Visualization also allows us to see relationships and correlations between different variables, providing insights that may be missed when looking at data in a tabular format.

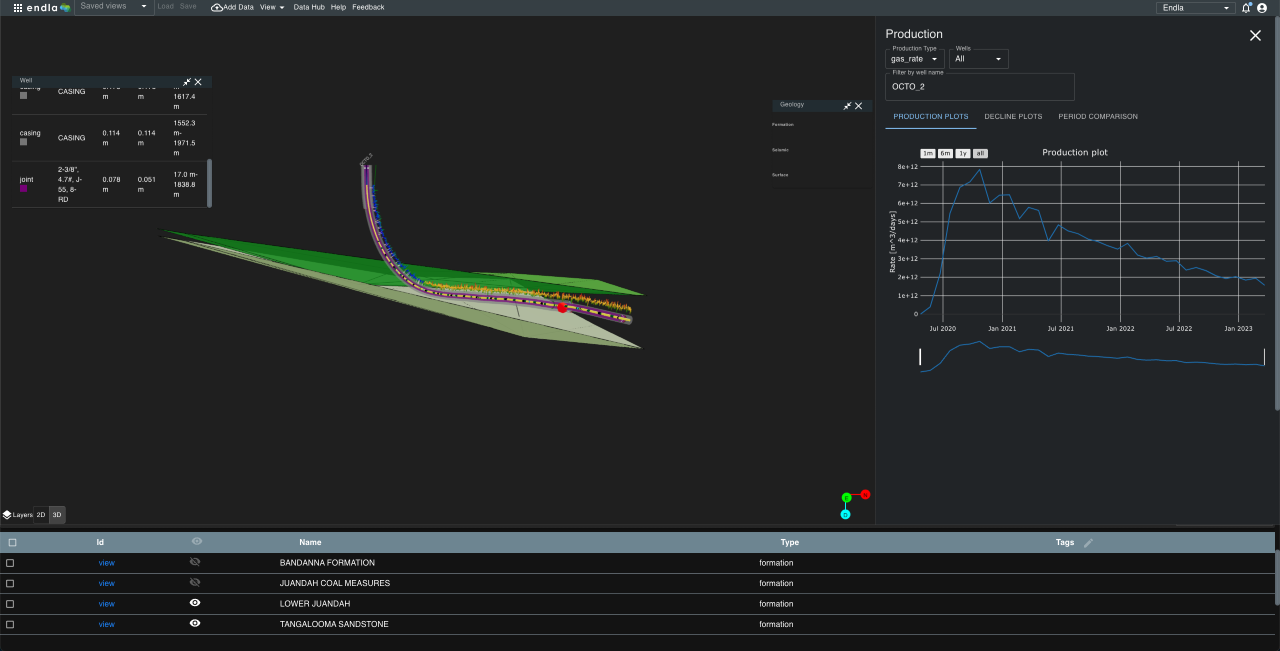

Deep Insight enables engineers to cycle through several different data types to identify any patterns or anomalies. In this example, when reviewing the "formation tops" data, it could immediately be seen, using 3D visualisation, that all the wells with casing failure were in the same geological dipping formation. This insight is crucial in diagnosing problems and finding a solution.

Contrasting what can be achieved using Deep Insight; Imagine trying to pick out this trend in thousands of rows of data in excel, even just analysing the spatial component of it is hard enough let alone layering in the other variables. What might be a 5 minute exercise in Deep Insight could take multiple days if not weeks in Excel.

Using the annotation function, the problematic wells are labelled and the identified issue is flagged. Relevant teams are notified through Deep Insight's Digital Twin as they are tagged in the annotation, which creates a notification for those team members. This streamlines communication and ensures that the right people are informed about the issue. The design philosophy is then updated to ensure that the problem is avoided in the future.

Using Deep Insight the oil and gas company can then use this example, along with other design approaches, to build visual training tools for existing staff and when on boarding new staff. The visual nature of the data model means that it is very effective as a training tool to ensure that everyone can understand the subsurface formations, the well designs and the outcomes which are achieved. As the design philosophy evolves so does the training and communications for the team.

Deep Insight, as a Digital Twin, is a valuable tool for the unconventional oil and gas industry. Its visualization and annotation capabilities, combined with real‑time data updates, help identify patterns and communicate issues effectively to the right people.

The actionable insights provided by Deep Insight to avoid significant loss in production and revenue is just one way it helps tighten the feedback loop to improve the value of your wells. In future posts we'll explore more ways Deep Insight can add value to your company.